Technical Data

Products »WEB Catalog » Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other) » Gripper for Collaborative Robots

Products »WEB Catalog » Gripper for Collaborative Robots » For the OMRON Corporation and TECHMAN ROBOT Inc.

Products »WEB Catalog » 【特設】Gripper for Collaborative Robots » For the OMRON Corporation and TECHMAN ROBOT Inc.

・Plug and Play configuration for immediate use

・TMComponent: Easy programming

・Attracts and holds heavy objects with a magnet

・Supports workpieces with holes and uneven surfaces

・Compact with high holding force

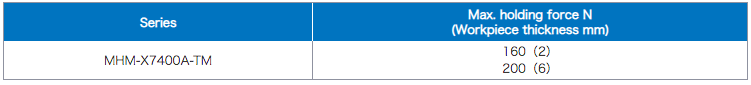

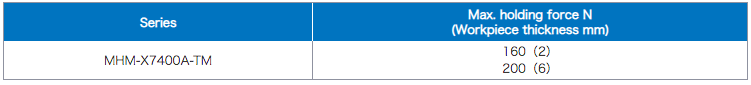

Holding force: Max. 200 N (ø25, Workpiece thickness 6 mm)

・Continues to hold workpieces even when the air is shut off

・Operate by simply connecting 1 air supply tube and an electrical wiring M8

connector.

・Integrated solenoid valve, auto switch, and piston speed adjustment mechanism

Other Data :

> Safety Instructions

> Vacuum Equipment/Precautions

> Green Procurement (RoHS)

■Attracts and holds heavy objects with a magnet

■Characteristics

Holding force

The holding force graph shows the theoretical value for low-carbon steel plates.

Holding forces vary depending on the material and shape of the workpiece. Please perform a holding test while referring to the value selected based on the graph.

■FANUC CRX Plug-in Software

Easy programming

Using the certified software TMComponent of OMRON Corporation and TECHMAN ROBOT Inc., various operations and sensor signals can be easily programmed by using a control box equipped with the dedicated software tool “TMflow” or by using graphical flowcharts on a Windows computer.

You can easily install the software by inserting a USB with the TMComponent software package into a control box or Windows computer.

∗ Please download the TMComponent software package from the SMC website, and save it to a USB memory.