Technical Data

・Thinnest: 40 mm thick

・Fastest: Rapid static neutralization 0.5 seconds

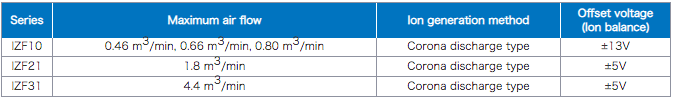

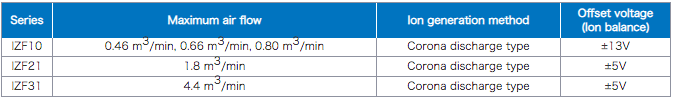

・Offset voltage (Ion balance): ±5 V

・Stable static neutralization performance, Easier maintenance

Other Data :

> Safety Instructions

> Green Procurement (RoHS)

■Extensive rapid static neutralization

Extensive static neutralization

Extensive static neutralization area can be covered with adjustable louver.

Rapid static neutralization

■Stable Static Neutralization Performance, Easier Maintenance

The emitters life is almost doubled with averaging function.

Built-in sensor constantly monitors offset voltage.

Automatic balance adjustment function achieves stable offset voltage and reduces adjustment time.

Emitter contamination can be reduced by automatic cleaning function.

Cleaning arms are installed inside. Emitter cleaning is started by external input or operation button.

Contamination of the emitters can be detected.

Emitter contamination level is constantly monitored. When maintenance is required, the user is alerted by a signal output and the LED turning ON.

Emitter cartridge is easily replaceable. (No tools are required.)

■Flow Rate Adjustment Function

Flow rate is adjustable in 10 steps using the flow rate adjustment dial. The flow rate adjustment dial is removable to prevent unexpected changes of adjustment.

■Application Examples

Neutralizing static electricity on PET bottles

Trip-resistance during conveying/

Prevents adhesion of dust.

Neutralizing static electricity on film molded goods

Sticking and scattering prevention on a conveyor

Static neutralization on packaging materials made from polystyrene foam.

Darkening due to dust adhesion prevented

Neutralizing static electricity from packing films

Prevents the filled substance from adhering to the packing film and reduces packing mistakes.