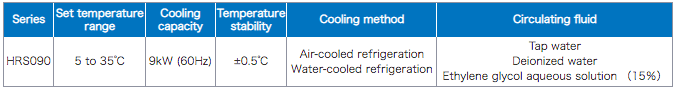

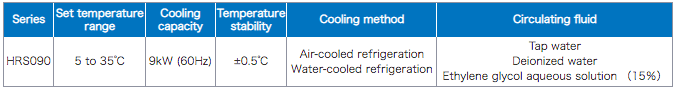

Technical Data

・Lightweight and compact

・Cooling capacity: 9 kW

・Temperature stability: ±0.5°C

・Set temperature range: 5 to 35°C

・Max. ambient temperature: 45°C

・Power supply: 3-phase 200 to 230 VAC, 380 to 415 VAC, 460 to 480VAC

Other Data :

> Safety Instructions

> Temperature Control Equipment/Precautions

> Features/Series Variations

> Technical Data

> Can be used in a wide range of applications!

> Temperature Control Equipment Warranty

> Green Procurement (RoHS)

The precision temperature control method by expansion valve and temperature sensor, realized high temperature stability of ±0.5°C and a small-size tank.

Reduced-height double condenser structure

■Globally compatible power supplies

Europe, Asia, Oceania, North, Central and South America: Only 400/460 VAC type

■Communication function

The serial communication (RS232C/RS485) and contact I/Os (2 inputs and 3 outputs) are equipped as standard. Communication with the user’s equipment and system construction are possible, depending on the application.

A 24 VDC output can be also provided, and is available for a flow switch (SMC’s PF2W etc.).

■Applications

Resistance welding machine

(spot welding)

Cooling of the welding head electrodes, transformers and transistors (thyristors)

High frequency induction heating equipment

Cooling of the heating coils, high frequency power source and around inverters