Technical Data

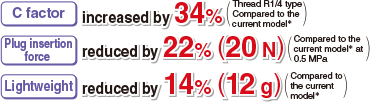

・Cv factor: Increased by 34%*

・Plug insertion force: Reduced by 22% (20 N)*

・Lightweight: Weight reduced by 14% (12 g)*

* Compared to the existing model

Other Data :

> Safety Instructions

> Fittings and Tubing/Precautions

> Series Variations

> Green Procurement (RoHS)

■With lock mechanism (Semi-standard)

Removal by unexpected impact can be prevented.

Locked and released position can be maintained by the detent on the sleeve.

■Energy saving and cost reduction

Since pressure loss is smaller than the current product (KK13 series), even if inlet pressure is reduced, equivalent outlet pressure and flow rate can be achieved when it is used for air blow.

It is possible to reduce the cost with lower air and energy consumption of compressors.

■Inlet pressure and compressor electric power cost against operating flow rate (per coupler)

[Calculation conditions]

Operating pressure at the outlet: 0.5 MPa

Compressor efficiency: 0.7

Electric power cost: 15 yen/kWh

Annual operating time: 2500 hours

■Cost reduction effect by using S couplers in a factory

It is possible to achieve a large cost reduction when looking at the effect on a factory scale.

[Calculation conditions]

50% of the total air consumed in the factory passes through the S coupler, and 4 S couplers are used at the end of the line.

Operating pressure at the outlet: 0.5 MPa Air consumption of one line at end: 1.2 m3/min (ANR) Air consumption time: 20% of annual operating time of 2500 hours

Compressor efficiency: 0.7

Electric power cost: 15 yen/kWh

Compressor capacity: 8 m3/kWh