Technical Data

・For UHP gas delivery in semiconductor and other clean industries

・Used as a gas shutoff valve

・No spring is used for the wetted parts and the drive part is also separated

from the diaphragm. Dead space in the flow path is small in order to suppress

particle generation.

Other Data :

> Safety Instructions

> Process Gas Equipment/Common Precautions

> Series Variations

> Valve and Regulator Recommendations

> Technical Data/Glossary of Terms

> Green Procurement (RoHS)

■Regulator/Back Pressure Regulator for General Applications Series AK/BP

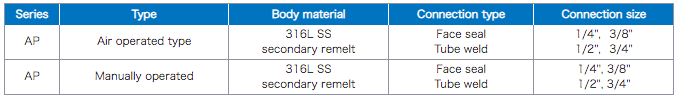

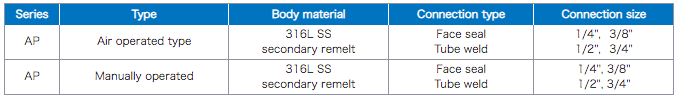

■Diaphragm Valve for Ultra High Purity Series AP

■Check Valve/Vacuum Generator/Flow Switch Series AP

[Check valve]

[Vacuum generator]

[Flow switch]