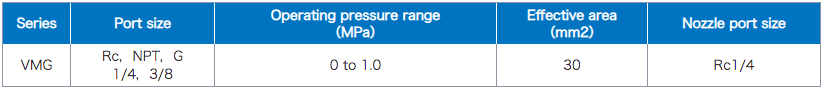

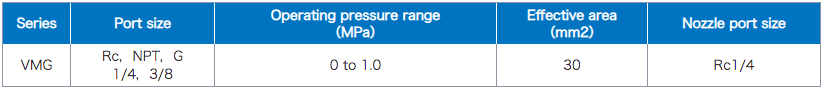

Technical Data

・A 20% reduction in power consumption can be achieved with

the SMC “Blow gun” + “S coupler” + “Coil tube.”

・Pressure loss: 1% or less (Nozzle size: ø2.5)

・Available nozzles:

Male thread nozzle, High efficiency nozzle with male thread,

Low noise nozzle with male thread, Copper extension nozzle

・With flow rate adjustment function (-X54)

Other Data :

> Safety Instructions

> Selection/Technical Data

> Green Procurement (RoHS)

■Amount of electricity used in a factory

The electricity used by compressors for air accounts for approximately 20% of that consumed by the entire factory. Also, 70% of the air consumed in the process is used for air blowing. SMC blow guns have minimal pressure loss compared with conventional models, so they can achieve equivalent performance at lower pressures and with less volume of air consumption. As a result, it is possible to achieve a 20% reduction in power consumption.

■Operability, Safety, Environment

Not affected by supply pressure, assured operability

When using this product even at a high pressure, the same gripping force is required as for a lower pressure due to the unique balance-poppet construction.

Components are separable.

Environmentally friendly

Resin parts are inscribed with the name of the material.

Additionally, all parts can be separated by material.