Technical Data

・For the adsorption transfer of thin cloths, films, printed circuit boards, etc.

・Energy saving: Max. 72% reduction (Comparison of air consumption to lifting

force)

・High lifting force: 28.3 N

5.7 times that of the existing model (Existing model: 5.0 N → ZNC60: 28.3 N)

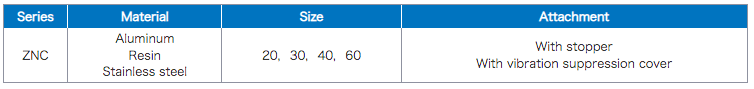

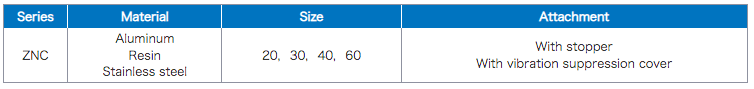

・3 types of body materials: Aluminum, Resin, Stainless steel

・Attachments

With stopper: Prevents workpiece slippage

With vibration suppression cover: Suppresses the vibration noise of thin

workpieces

Other Data :

> Safety Instructions

> Vacuum Equipment/Precautions

> Series Variations/Model Selection

> Green Procurement (RoHS)

■Basic type (Without vibration suppression cover/stopper)

When a flat, hard, non-breathable workpiece such as glass is adsorbed, it will be gripped without direct contact.

As the gripper approaches the workpiece, the flow speed of the air flowing between the gripper and the workpiece increases, creating a vacuum and adsorbing the workpiece. In the case of a flat, hard, non-breathable workpiece such as glass, it will be in a non-contact state. The lifting force of the gripper and the weight of the workpiece is balanced around 0.2 to 0.5 mm.

■With stopper

The rubber stopper prevents the workpiece from sliding.

By attaching stoppers, the state changes from non-contact to contact and the workpiece is gripped. For flat and hard workpieces such as glass, it is recommended to have stoppers to prevent slipping. When using a soft workpiece such as cloth or paper, it may come into contact with the gripper and generate vibration noise. In this case, it is recommended to have a vibration suppression cover.

* Only the rubbers of the stopper can be replaced.

* The stopper reduces the lifting force.

■With vibration suppression cover

Suppresses the vibration that occurs when a soft workpiece such as cloth or paper is adsorbed

The vibration suppression cover suppresses the vibration generated when a soft workpiece, such as cloth or paper, comes into contact with the gripper, and reduce the generation of sound. Air flows at high speed in the gap between the vibration suppression cover and the workpiece, enabling stable suction transfer. * With the vibration suppression cover, the status is changed to contact instead of non-contact.

* The vibration suppression cover reduces the lifting force.

■Construction and working principle

Clean air is discarded from the inside to the outside. There is no clogging of foreign matter.