Technical Data

・Low particle generation, Oil-free, Metal-free * Fluid contact parts

・Isolated structure

The solenoid drive body is separated from the fluid area by a diaphragm.

・Power consumption: 1.0 W or less (With power saving circuit)

・Change in volume (Pumping volume): 0.01 µL or less

Other Data :

> Safety Instructions

> 2 Port Solenoid Valves for Fluid Control Precautions

> Model Selection/Flow Rate Characteristics

> Series Variations/Solenoid Valves List

> Green Procurement (RoHS)

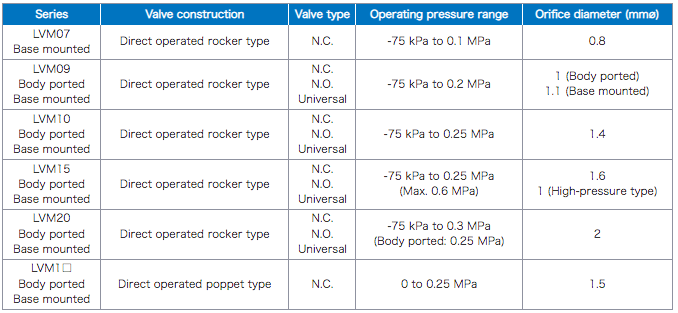

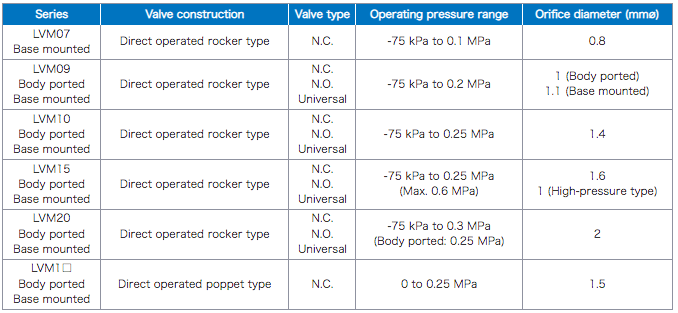

■Direct Operated Rocker Type /LVM07・09/090・10/100・15/150・20/200

・Isolated structur

The solenoid drive body is separated from the fluid area by a diaphragm.

・Change in volume (Pumping volume): 0.01 μL or less

With a normal diaphragm valve, because the valve chamber volume varies depending on the ON or OFF status, the difference in volume is discharged into the outlet side of the valve when the valve is switched from ON to OFF.

However, with a rocker type valve, there is almost no change in volume, and thus no fluid is discharged into the outlet side of the valve.

・A type with a power saving circuit can be selected.

Holding power consumption can be reduced substantially.

Continuous energization for extended periods of time is possible.