Technical Data

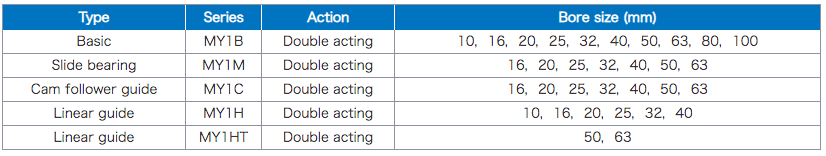

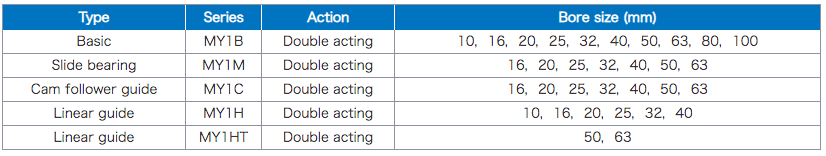

・With 5 standardized guide types

・A variety of applications are available based on the load mass and

required accuracy.

Other Data :

> Safety Instructions

> Actuators/Precautions

> Auto Switches/Precautions

> Model Selection/Technical Data

> Quick Selection Tables

> Made to Order Common Specifications

> Green Procurement (RoHS)

■Minimal leakage seal construction

The flexible material of the seal belt allows for improved adherence to the cylinder tube, resulting in a reduced leakage amount.

(50% reduction compared with the current product)

■Dust seal band with improved holding force

The seal magnet on the cylinder tube adsorbs the dust seal band with magnetic force, resulting in improved holding force.

The dust seal band can be easily removed for replacement by simply loosening the two holding screws.

Easier maintenance

■Allows for piping to be connected according to installation conditions. Centralized piping type for increased piping freedom

■MY1M and MY1C compatibility guaranteed

With the same outer dimensions and workpiece mounting dimensions, both series are compatible with stroke adjustment units, side supports, auto switches, etc.

■Auto switch wiring storage system To increase safety, auto switch lead wires can be stored to prevent accidental contact with slide tables.

Improved safety and accuracy of the entire system can be achieved by storing auto switch lead wires in the product’s designated lead wire containment grooves.